- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

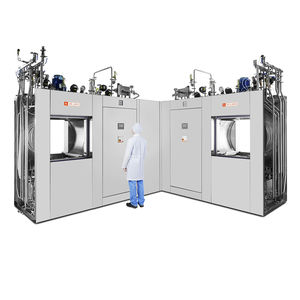

Medical sterilizer DLVHP/STlaboratoryfor the pharmaceutical industryhydrogen peroxyde

Add to favorites

Compare this product

Characteristics

- Applications

- medical, laboratory, for the pharmaceutical industry

- Sterilization procedure

- saturated steam, hydrogen peroxyde

- Configuration

- floor-standing, horizontal

- Function

- automatic, low-temperature, high-capacity

- Sterilization chamber material

- stainless steel

- Options

- with touchscreen, with sliding door, custom-made

- Capacity

Min.: 150 l

(39.63 gal)Max.: 80,000 l

(2,825.17 gal)- Temperature range

Min.: 30 °C

(86 °F)Max.: 42 °C

(107.6 °F)- Sterilization cycle time

Min.: 3 h

Max.: 5 h

Description

De Lama has developed an innovative process starting from its many years of experience in the sterilization field: HyPerPure® Low temperature Sterilization technology with Hydrogen Peroxide under deep vacuum and zero air.

HyPerPure® Sterilization technology is a proprietary solution by De Lama operated with De Lama DLVHP/ST equipment.

It’s a low-temperature sterilization process representing the real alternative to ETO (Ethylene Oxide) and Gamma Rays sterilization, and offering important advantages compared to these more traditional techniques

Thermo-labile finished products can be fully sterilised in the most recessed cavities.

The peculiarity of the use of the vacuum technology allows gas full penetration into the widest variety of packaging. Vacuum system is composed by multiple step high vacuum system to allow the most effective sterilization phase and gas removal at cycle end.

The sterilisation cycle work in an open loop, without any consumable, and grant a very high level of repeatability

DESIGN & CONSTRUCTION FEATURES

semi-automatic hinged doors or automatically sliding doors or new Magnetodoor® magnetic driven door.

direct ventilation in chamber with magnetic coupling fan to improve hydrogen peroxide circulation open loop configuration with catalyst (no consumables) on exhaust

WHY IS IT THE GREENEST STERILIZER IN THE WORLD?

The process is at low temperature with no thermal energy waste as occurs in hot sterilization processes (such as, for example, with saturated steam sterilization)

VIDEO

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Autoclave

- Steam autoclave

- Medical autoclave

- Automatic autoclave

- Stainless steel autoclave

- Laboratory furnace

- Laboratory autoclave

- Cleaner-disinfector

- Front-loading sterilizer

- Floor-standing autoclave

- Vertical autoclave

- 1-door furnace

- Autoclave with touchscreen

- Stainless steel furnace

- Floor-standing cleaner-disinfector

- Front-loading washer-disinfector

- Drying furnace

- Pass-through

- Autoclave with steam generator

- High-capacity autoclave

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.