- Laboratory >

- Physico-chemical analysis >

- Degassing module

Degassing modules

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

... The Sykam S 7515 Vacuum Degasser is a highly efficient vacuum solvent degasser for HPLC. The S 7515 uses Teflon-AF® as degassing capillary resulting in a low dead volume of less than 500 µl per channel. Teflon-AF® ...

... separation therefore requires degassing of the solvent. The small analytical 2-channel degasser DG 2.1S is equipped with two degassing chambers and can thus degas two solvents simultaneously. TECHNICAL ...

KNAUER

... semi-preparative KNAUER online degasser module can be used for flow rates of up to 30 ml/min per channel. TECHNICAL DATA Degasser channels - 2 Max. flow rate/channel - 30 ml/min Recommended flow rate/channel - ...

KNAUER

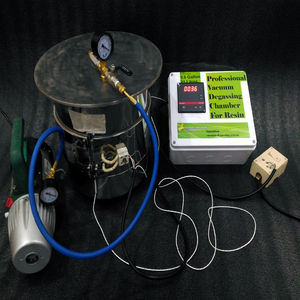

VACUUM DEGASSING CHAMBER Vacuum degassing is the process of using vacuum to remove gases from compounds which become entrapped in the mixture when mixing the components. To assure a bubble-free mold ...

Meditech Technologies India

A pressure pot for resin casting manufactured by Burhani Hardware And Fittings is required for bubble-free and air-trap-free resin castings. This is especially critical in creating clear resin castings applications, as trapped air can ...

Meditech Technologies India

VACUUM DEGASSING CHAMBER Vacuum degassing is the process of using vacuum to remove gases from compounds which become entrapped in the mixture when mixing the components. To assure a bubble-free mold ...

Meditech Technologies India

VACUUM DEGASSING CHAMBER Vacuum degassing is the process of using vacuum to remove gases from compounds which become entrapped in the mixture when mixing the components. To assure a bubble-free mold ...

Meditech Technologies India

VACUUM DEGASSING CHAMBER Vacuum degassing is the process of using vacuum to remove gases from compounds which become entrapped in the mixture when mixing the components. To assure a bubble-free ...

Meditech Technologies India

VACUUM DEGASSING CHAMBER Vacuum degassing is the process of using vacuum to remove gases from compounds which become entrapped in the mixture when mixing the components. To assure a bubble-free mold ...

Meditech Technologies India

VACUUM DEGASSING CHAMBER Vacuum degassing is the process of using vacuum to remove gases from compounds which become entrapped in the mixture when mixing the components. To assure a bubble-free ...

Meditech Technologies India

VACUUM DEGASSING CHAMBER Vacuum degassing is the process of using vacuum to remove gases from compounds which become entrapped in the mixture when mixing the components. To assure a bubble-free mold ...

Meditech Technologies India

Heated Vacuum Degassing Chamber Heated Vacuum degassing is the process of using vacuum to remove gases from compounds which become entrapped in the mixture when mixing the components. To assure a ...

Meditech Technologies India

Heated Vacuum Degassing Chamber Heated Vacuum degassing is the process of using vacuum to remove gases from compounds which become entrapped in the mixture when mixing the components. To assure a ...

Meditech Technologies India

Externally, degassing chambers do not differ much from pre-conditioning chambers. However, they perform a completely different function and represent the last step that completes a standard sterilisation cycle. In ...

The S 8515 vacuum degasser is an online degasser system with high efficiency. Dissolved gases are removed from the solvents by applying vacuum to a semi- permeable membrane. High efficiency The high efficient Teflon-AF® capillary ...

Your suggestions for improvement:

the best suppliers

Subscribe to our newsletter

Receive monthly updates on this section.

Please refer to our Privacy Policy for details on how MedicalExpo processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining