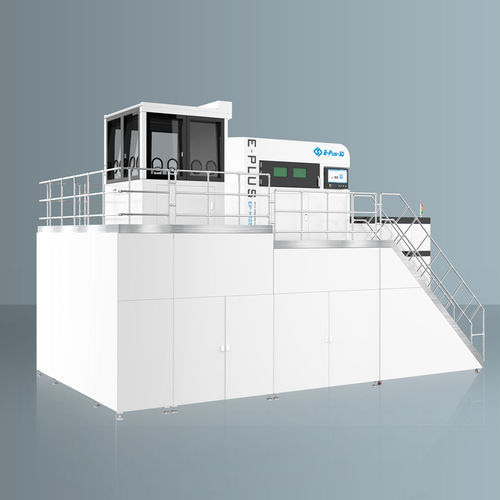

Laboratory 3D printer EP-M1250powder bed fusionmetalmetal

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Applications

- laboratory

- Technology

- powder bed fusion

- Other characteristics

- metal, metal, aluminum, titanium

Description

Using MPBF (Metal Powder Bed Fusion) technology, the EP-M1250 is using a 1258 x 1258 x 1350 mm3 build envelope and nine laser systems to ensure a high efficiency production. The precise positioning and innovative area splicing control technology offers uniformity and stability throughout the whole printing phase.

The system can operate with various metal powders such as Titanium, Aluminum and Nickel-based alloys, Maraging Steel, Stainless Steel, Chrome Cobalt Alloys and other materials. It is suitable for the direct manufacturing of large size, high-precision and high-performance parts in the aerospace, aviation, automotive, machinery and oil & gas industry.

Printing of mass-individualized parts in the 2136 Liter (1258 x 1258 x 1350 mm3 ) build chamber.

Each of the nine lasers covers its own area for maximum efficiency.

Bi-directional powder re-coating method leads to reduced re-coating time.

Excellent high beam quality (M2≤1.1).

Printed parts' density > 99.9 %, deviation in parts' mechanical properties < 5 %.

The optimized gas flow design ensures efficient removal of smoke and splashes as well as achievement of uniform and consistent full size printing.

The strict calibration ensures the consistency between parts and batches.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Eplus3D‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.