- Medical Technical Facilities

- Hospital infrastructure

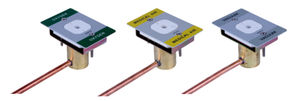

- DIN outlet

- Jiangsu Fuyou Medical

DIN outlet FY-GTDBfor medical gas pipeline systemsmedical gas

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Type

- DIN

- Use

- for medical gas pipeline systems

- Options

- medical gas

Description

. Process and manufacture according to EN737-1:1998, DIN13260-2, ISO9170-1, IS09170-2 standards, and obtain CE certification.

2. 100% airtightness test.

3. 10000 insertions and removals without any malfunctions.

4. Identify gases using the ISO32 color standard.

5. Use different socket shapes to distinguish different gases.

6. There are multiple installation methods, including an intake pipe with an outer diameter of 8, a gas pipe joint, or a threaded interface.

7. The types of gases include oxygen, suction, air, nitrogen, laughing gas, carbon dioxide, etc. 8. The terminal material is high-quality copper, and the sealing ring is made of imported materials.

9. Secondary plugging and unplugging to prevent accidental removal and ensure personal safety.

10. Installation methods: wall mounted, tower mounted, equipment belt mounted, etc.

11. Equipped with a detachable protective cover.

12. The German all metal series terminals also have the function of non dismantling equipment with the ability to repair gas terminals, while meeting the conditions of 1-11 mentioned above, and each gas socket has specificity for its base.

Catalogs

No catalogs are available for this product.

See all of Jiangsu Fuyou Medical‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

China International Medical Equipment Fair

26-29 Sep 2025 guangzhou (China) Hall Canton Fair Complex (No.380YuejiangMiddleRoad,Guan - Stand Booth No www.fuyou med.com 1.1A38/1.1H

More information

Related Searches

- Healthcare facility door

- Sliding door

- Medical gas outlet

- Protection door

- Stainless steel door

- Laboratory door

- Digital control unit

- Manifold

- Medical device controller

- Medical controller

- Pressure control system

- Medical gas manifold

- Double-leaf door

- Radiation protection door

- DIN outlet

- Clean room door

- Insulation door

- Flow controller

- Controller with touchscreen

- Automatic manifold

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.