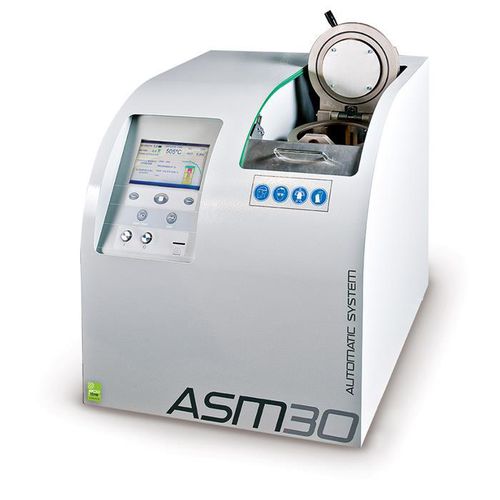

Dental vacuum casting machine ASM 30induction

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Operation

- vacuum, induction

Description

The ASM 30 model casting machine is a fully automatic pressure die-cast casting machine. The casting process is activated by a single movement: vacuum production, overturning, compression and cooling all take place automatically.

ASM 30 has the following accessories:

assorted pots

variously-sized cylinders

rubber bases (various sizes)

1 cylinder pliers

1 protection goggles

1 package of deoxidising tablets

The heating element is the core of the whole casting machine. It is a vital component on which Tecno-Gaz has concentrated its investments.

This heating element is a powerful combination of the best chemical and mechanical technologies. In-depth studies and the contribution of several other companies were necessary to develop a product that offers extraordinary performances and total reliability.

All the electrical contacts are managed by an aluminium rod system which, being different from common electrical cables, does not require expensive cooling systems and periodical maintenance operations.

The heating element has a safe assembling system, designed to absorb shocks and withstand high temperatures with no negative consequences.

The heating element consists of a sealed block that houses the resistor, isolated by a ceramic muffle ensuring resistor isolation and protection. The lower part contains the connection block and the junction box blocking system. The upper part contains the site to insert the crucible.

Helpful hints

Use only Tecno Gaz spare parts and accessories

Casting machine servicing must be done only by Tecno Gaz authorised technicians.

The crucible must be changed before each casting.

Catalogs

Related Searches

- Stainless steel furnace

- Dental milling machine

- CAD/CAM machining centre

- Dental laboratory furnace

- 5-axis machining centre

- Resin milling machine

- Dental wax milling machine

- PMMA milling machine

- Wet machining milling machine

- Dry machining milling machine

- Dental laboratory milling machine

- Dental composite milling machine

- Spindle milling machine

- CoCr milling machine

- Pneumatic dental sandblaster

- Compact furnace

- Zirconia furnace

- 1-tank dental sandblaster

- Dental casting machine

- Compact machining centre

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.