- Products

- Sterilization tunnel

- Wallstein Pharmaceutical Equipment(Haining) Co., Ltd

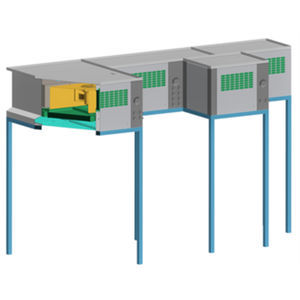

Sterilization tunnel depyrogenationmodular

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Applications

- sterilization, depyrogenation

- Other characteristics

- modular

Description

Wallstein has been a trusted partner to the pharmaceutical industry for over two decades and has manufactured more than 1,000 sterilization tunnels for a wide range of applications. These systems play a central role in the sterilization and depyrogenation of glass containers such as ampoules, cartridges or bottles, which are used for packaging liquid or powdered medicines. Microorganisms and pyrogens are thermally inactivated by a dry, hot air flow, which is guided according to the laminar flow principle. Precise adherence to defined temperature curves over a specified period of time is of crucial importance.

Our sterilization tunnels are based on a modular system that can be flexibly adapted to the specific requirements of our customers. The systems consist of three main assemblies: Infeed, heating section and cooling section. A cleaning machine is always installed upstream, while filling and packaging machines are installed seamlessly downstream.

In the infeed, the pre-washed glass containers are gently picked up and preheated to operating temperature. Sterilization and depyrogenation take place in the heating section at temperatures of over 300 °C. The containers are then slowly cooled down to the desired outlet temperature in the cooling section before being transferred to the filling machine.

High-quality materials such as stainless steel ensure durability and corrosion resistance. Precise temperature control is ensured by thermocouples that record exact temperature data. Filters and fans ensure even air distribution within the system.

Catalogs

No catalogs are available for this product.

See all of Wallstein Pharmaceutical Equipment(Haining) Co., Ltd‘s catalogsOther Wallstein Pharmaceutical Equipment(Haining) Co., Ltd products

Pharma technology

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.