- Products

- Orthopedic drill bit

- Zoray Precision Technology

- Products

- Catalogs

- News & Trends

- Exhibitions

Carbide drill bit orthopedicsurgicalpolishing

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Applications

- orthopedic, surgical

- Material

- carbide

- Function

- marking, grinding, polishing

- Length

Min.: 50 mm

(2 in)Max.: 150 mm

(5.9 in)- Diameter

Min.: 2 mm

(0.08 in)Max.: 6 mm

(0.24 in)

Description

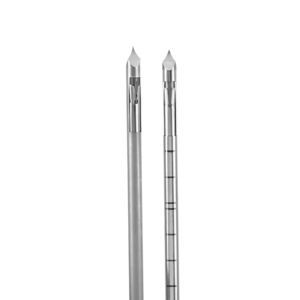

ZorayPT’s custom bone drill bit for fracture fixation (diameter 1.5mm-5.0mm, length 60mm-250mm, customizable) offers types like Solid, Cannulated, Fluted, and AO Type. Our one-stop OEM/ODM solutions deliver superior quality, faster lead time, and cost-efficiency.

Description

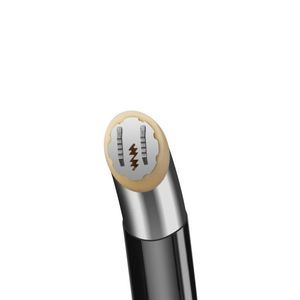

Custom Carbide Bur by ZorayPT

ZorayPT’s carbide bur is a precision-engineered tool designed for efficient cutting and shaping in various surgical procedures, ensuring durability and high performance. As a leading one-stop OEM/ODM manufacturer, with all in-house plastic molding, metal processing, and cleanroom assembly, we deliver superior quality custom carbide burs with diameters ranging from 2.0mm to 6.0mm (customizable), lengths from 50mm to 150mm (customizable), and a standard shank of 6.35mm (customizable). Produced in our ISO 13485-certified Class 100,000 cleanroom, these carbide burs are crafted from high-quality carbide for enhanced durability and wear resistance, offering a variety of tip styles, including Round, Ball, Fluted Round, Barrel, Pear-shaped, Cone, or fully customized to meet specific surgical needs. This device is ideal for carbide cutting and shaping, providing precision and reliability in procedures such as bone cutting, tissue preparation, and implant preprocessing across specialties. ZorayPT can tailor carbide burs based on client-provided samples, drawings, or specifications, offering advanced manufacturing processes such as Multi-faceted grinding, Marking, Bending, Drilling, Head forming, Taper reduction Flaring, Threading, Chamfering, Flanging, Grooving, Flattening, Diameter changing, Developing, Polishing coating, Syringe base, Base mold,

Other Zoray Precision Technology products

Featured Products

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.