- Dental

- Dental laboratory

- Dental 3D printer

- 3D Systems

- Products

- Catalogs

- News & Trends

- Exhibitions

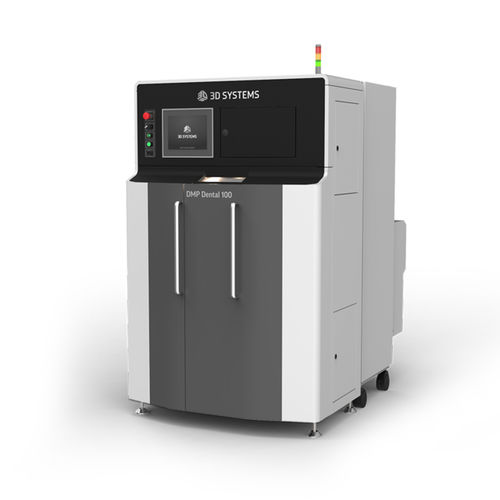

Dental 3D printer DMP 100floor-standingmetal

Add to favorites

Compare this product

Characteristics

- Applications

- dental

- Configuration

- floor-standing

- Other characteristics

- metal

Description

High Productivity Paired with Shortest Post Processing

Due to its higher power the 3D Systems entry level dental metal 3D printer now achieves up to double the productivity of its predecessor ultimately leading to reduced per part cost and faster delivery times. Print more than 90 crowns within under 4 hours, in one single print-run. DMP Dental 100 runs with a proprietary roller and very small powder particle sizes, leading to the shortest post processing time in the market. For the 90 crowns for example, stress relieve takes no more than 25 minutes.

Best surface finish, less supports

With a superior surface finish quality less post-processing is required. Improved surface quality ultimately mean less of the labor intensive post processing and less material usage for your laboratory –saving time and cost.

Outstanding accuracy for the perfect fit

The typical accuracy is +/-0.002 inches (+/-50 μm), allowing a perfect fit for every patient. Repeatability from part to part is approximately 0.0008 inches (20 μm).

Dental software to streamline workflow in laboratories

To streamline your workflow, the DMP Dental 100 printer comes with LaserForm CoCr (C) material (ISO 13485, ISO 9001, FDA and CE qualified) and includes a high-performance software solution for managing the manufacture of fixed and removable dental prostheses. This seamless, intuitive interface quickly guides you from dental file import to the creation of manufacturing files.

Excellent Surface Quality

Manufacture small, dense, complex dental prostheses with excellent surface quality and short post-processing at high productivity. High-performance dental software solution streamlines your workflow.

VIDEO

Catalogs

No catalogs are available for this product.

See all of 3D Systems‘s catalogsRelated Searches

- Dental material

- Restoration dental material

- PMMA dental material

- Dental prosthesis dental material

- Modeling dental material

- Dental crown material

- Dental bridge material

- Biocompatible dental material

- Wax dental material

- Casting dental material

- Translucent dental material

- Dental laboratory dental material

- Composite dental material

- 3D printer

- 3D printing dental material

- Impression tray dental material

- Opaque dental material

- Orthodontic material

- White dental material

- Transparent dental material

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.