- Products

- CSV Containment

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

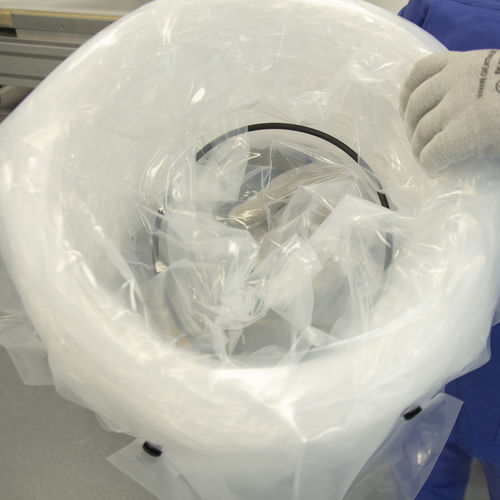

Continuous liner

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Foil diameter

Max.: 23 in

Min.: 4 in

- Foil thickness

Max.: 150 µm

Min.: 60 µm

- Liner length

Max.: 40 m

(131'02" )Min.: 0 m

(0'00" )

Description

CONTINUOUS LINER

Continuous liners are born from our vast experience in the containment world. Tailor-made products of different sizes, shapes and colours are designed and packaged in Italy.

Besides continuous liner, the Flexilab works in synergy with the production of bags for flexible isolators and processes the best films available on the market. The materials used are constantly being improved, increasing their strength and transparency and reducing their thickness without reducing their sealing quality. Continuous liners guarantee high containment packaging, extreme ease of use and remarkable effectiveness in containing active pharmaceutical ingredients (APIs).

They can be made in doughnut shape, but also in folded version.

Main features:

- Made of Antistatic LDPE.

- Antistatic treatment valid up to 1 year after production.

- Donut Shape with welded o-ring.

- Lengths available: from 5 to 25 meters (anyway customable).

- Thicknesses available: 60, 70, 80, 90, 100, 120 μm.

- Heights available: 22, 36, 50, 55, 70, 80, 90, 100 cm.

- Suitable for food contact in compliance with FDA requirements – Federal Code, Regulation 21 CFR.

- Pharmaceutical and Biomedical Use in compliance with European Pharmacopoeia paragraph 3.1.3-4-5, USP paragraph 87, 88, 661, 231.

- Atex Requirements with reference to directive 2014/34/EU.

Absence of:

- Impurities and Contaminants with reference to EU Guideline EMA / CHMP/ ICH/ 353369/2013.

- Allergenic Substances.

- Materials of Animal origins with reference to Regulation 1069/2009 – EC and 142/2011 – EC in addition to “Explanatory note EMEA/410/01, rev.3” about BSE/TSE (so-called mad cow).

- Phthalates and Nitrosamines.

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.