- Dental

- Dental laboratory

- CAD/CAM milling machine

- imes-icore GmbH

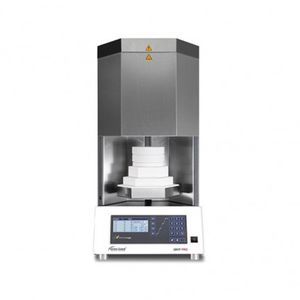

CAD/CAM milling machine CORiTEC 650i PRO seriesfor dental laboratories5-axis1-spindle

Add to favorites

Compare this product

Do you want to buy directly? Visit our shop.

Characteristics

- Type

- CAD/CAM

- Applications

- for dental laboratories

- Number of axes

- 5-axis

- Number of spindles

- 1-spindle

- Machining type

- dry machining, wet machining

- Configuration

- floor-standing

- Spindle speed

50,000 rpm

(314,159 rad.min-1)- Power

5,700 W

Description

CORiTEC® 650i PRO series

The Premium Class for 24/7 Production with Absolute Precision

Designed for laboratories and milling centers with premium demands aiming for highest precision.

Highlights:

- Solid axis construction made of ground natural granite for 5-axis simultaneous machining

- Linear and torque motor-driven machining axes

- Water-cooled spindle with 5,7 kW power and up to 50,000 rpm

- Direct measuring systems with 0.05 μm (26-bit resolution)

- 32-fold tool changer for maximum flexibility

- Fully automatic 16-fold blank changer for continuous operation (Loader version)

- EROWA zero-point clamping system (5,000 N retraction force)

- Open to all dental materials and indications

- Post-processing of metal prints (e.g., LPBF or laser-sintered frameworks, model castings, telescopes)

- Compatible with all common metal printing systems

Areas of application and possible indications:

Material processing:

All dental materials from ceramics to metals e.g.

- Glass ceramics and lithium disilicate

- zirconium

- Titanium and CoCr abutments

- Sintered metal

- Pre-Milled Abutments

- Hybrid materials such as PMMA, PEEK and composite

Indications/Applications:

- Crowns, Bridges, Onlays,...

- Bar and supra-constructions

- Hybrid milling

- Telescopic technology

- Turn milling of abutments

Why choose the CORiTEC® 650i PRO series?

This premium-class machine sets new standards for laboratories and milling centers, offering limitless possibilities for the highest demands. With unmatched precision, reliability, and versatility, it empowers your lab to master even the most complex dental workflows with ease and efficiency.

Catalogs

No catalogs are available for this product.

See all of imes-icore GmbH‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Dental material

- Restoration dental material

- Analysis medical software

- PMMA dental material

- Cupboard with drawer

- Dental prosthesis dental material

- Dental crown material

- Dental bridge material

- Medical equipment cabinet

- Biocompatible dental material

- Mobile cabinet

- Wax dental material

- Casting dental material

- Dental software

- Milling dental material

- Translucent dental material

- Design software

- 3D printer

- Dental facility cabinet

- Orthodontic material

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.