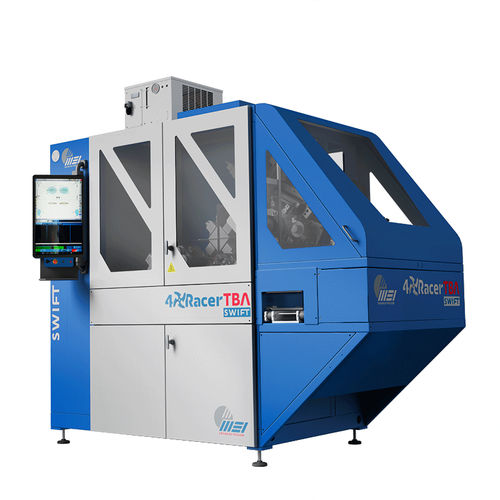

Optical lens edger 4RacerTBA Swiftoptical lens blockerautomatic

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Type of system

- optical lens edger, optical lens blocker

- Options

- automatic

Description

All you need in your lab for the lens inspection and mounting is packed inside MEI 4RacerTBA Swift, that features unparalleled automatic inspection abilities and fast self-controlled edging process, with the smallest physical and environmental footprint of the market.

New 4RacerTBA Swift, enriched now with new features, is the state of the art for inspection and edging of prescription lenses.

PRODUCTIVITY

The worlds most productive lens edger with the smallest footprint of the market

With its new control unit and the new lens loading program, the 4RacerTBA Swift improves further the already unmatched productivity of the 4RacerTBA.

BENEFITS

MEI milling technology

Dry cut

Cutting every kind of edge

Easily edge sport frames

Automatic calibration (optional)

User friendly software interface

Total quality control, like no other

Edging is just one part of the RX lens mounting process. Making sure that your customer receives the quality they deserve requires several inspection processes, before and after edging. This impacts labor costs, work space and delivery time, but this was before the 4RacerTBA Swift.

The 4RacerTBA Swift performs all needed quality inspection tasks without increasing the edging cycle, analyzing 100% of the production, minimizing the rejects and automatically applying the needed correction.

Throw the Block Away

With the integrated TBA (Throw the Block Away) system you can reorganize your manufacturing process avoiding to block/de-block the lenses.

Therefore you significantly reduce work, time and consumable costs because you no longer need to inspect/spot-up lenses, block or de-block lenses.

VIDEO

Catalogs

4Racer TBA Swift

9 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.