- Dental

- Dental laboratory

- Dental polymerizer

- NUOVA A.S.A.V. snc di Leoni Franco e Attilio

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

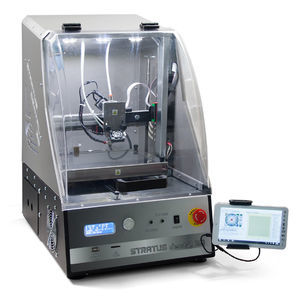

Dental polymerizer FMP 3D MAXI

Add to favorites

Compare this product

fo_shop_gate_exact_title

Description

Versatile device for curing 3D prints with 8 groups of 9 leds, for a total of 72 high-performance emitters covering frequencies from 385 to 425 nM.

The leds completely irradiate the transparent work surfaces and do not create structural stress during polymerisation The machine is equipped with a turntable that optimises exposure to UV radiation and a special 3-plane stand created to exploit the entire volume of the mirror-finished stainless steel chamber. Total capacity of 25/30 arcades per cycle or prints up to 25 cm high. Intuitive and safe for the operator with easy-to-operate protruding buttons and safety system on door opening.

FMP 3D N MAXI

A polymeriser model that allows the work cycle to be performed in a controlled atmosphere by direct injection of nitrogen into the chamber.

This technology improves the depth of cure by reducing exposure time and can be used to complete a certified working cycle.

With this process, smooth and non-stick surfaces are obtained, avoiding washing and saving time.

It is necessary to connect a cylinder of inert gas to the 6 mm diameter rear connection and adjust the outlet pressure to 1.5 Bar.

Voltage 220 V. %0 Hz.

Power (LED) 80 W.

Chamber Size 22 x 22 x 28 cm

Frequency Range: 380 – 425 Nm

External Dimension: 40 x 33 x 39 cm

Weight: 15 kg.

Catalogs

No catalogs are available for this product.

See all of NUOVA A.S.A.V. snc di Leoni Franco e Attilio ‘s catalogsOther NUOVA A.S.A.V. snc di Leoni Franco e Attilio products

Laboratories Line

Related Searches

- Oil-free air compressor

- Medical air compressor

- Agitator

- Dental air compressor

- Heating furnace

- Dry vacuum pump

- Medical light

- Micromotor

- Benchtop stirrer

- Benchtop furnace

- Electric micromotor

- Digital stirrer

- 1-workstation air compressor

- 3D printer

- Piston air compressor

- Blender

- Dental micromotor

- Air compressor with air dryer

- Laboratory air compressor

- Dental 3D printer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.