- Laboratory

- Sample management

- Automatic compounding system

- COLLIN Lab & Pilot Solutions GmbH

Automatic compounding system ZK serieslaboratoryfor the pharmaceutical industrymedical

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Operation

- automatic

- Applications

- laboratory, for the pharmaceutical industry, medical

- Preparation type

- cooling, degassing, mixing

- Sample type

- laboratory

- Configuration

- modular

Description

The P for Professional series compounders is the high-performance version among the COLLIN compounders. Correspondingly, they are also available as high-performance version for a process temperature of up to 500°C.

Advantages

Quick retrofitting between co and counterrotating

Modular design and different applications

Easy operability

Different applications

Modular screws for different mixing tasks

Different screw length for high flexibility

Standard design

With air cooling for a process temperature of up to 400°C

With water cooling for a process temperature of up to 350°C

High-temperature design

With air cooling for a process temperature of up to 500°C

With water cooling for a process temperature of up to 450°C

Materials

Polymers

Thermoplasts

Elastomers

Special materials

Highly filled materials

Application

Mixing and dispersing of pigments

Admixing of fillers and other additives into polymers

Admixing of fibres (glass fibre, carbon fibre)

Mixing of polymers or pastes

Degassing of volatiles

Continuous reaction extrusion

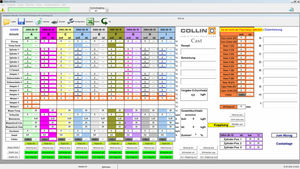

Control

The control is made via a touch screen CMI 17:

Screen size 17 inch

Display of all functions with set and actual values – tabularly, graphically or as bar diagram

Large display of important process values

Control button for all machine functions

Possibility of recipe management

Error and fault messages, language selection

Ethernet connection

Easy combination of the machines via Feldbus interface

Possibility of the connection to the superior SCADA system (for lines in the pharmaceutical production)

Customers

Raw material manufacturers

Compounding and refining companies

Processing companies

Universities and institutes

VIDEO

Catalogs

Other COLLIN Lab & Pilot Solutions GmbH products

LAB-Line

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.