- Laboratory

- Laboratory infrastructure

- Process control unit

- COLLIN Lab & Pilot Solutions GmbH

Production control system Roll Mill M & MRmedicallaboratoryprocess

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Type

- production

- Applications

- medical, laboratory, process, for the pharmaceutical industry

- Other characteristics

- with touchscreen

Description

COLLIN Roll Mills M Measuring are essential for all processes in development and production control.

The accuracy of the setting parameters and the large number of measuring devices allow a reproducible determination of characteristic material data, whereby the creation of optimal setting parameters for all production machines is supported.

If desired, gap measurements and controls as well as a design of a high-temperature version of up to 450°C are possible.

Advantages

Reproducibility

Large number of integrated measuring devices

Many options

Materials

Thermoplastics

Elastomers

Masterbatch

PVC

High-temperature version: up to 450°C

Application

Production

Laboratory – test, trials

Small batch test

Quality control

Control

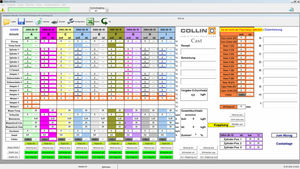

The control runs via a 7″ touch display (CMI 7) with operating buttons as well as data wheel and allows manual and automatic operation of the roll mill.

Display of all functions with set and actual values

Value display tabularly, graphically or as bar diagram

Large display of important process values

Operating buttons for all machine functions

Possibility of recipe management

Error and fault messages

Language selection

Ethernet connection, as option

Customers

Raw material manufacturers

Compounding and refining companies

Processing companies

Universities and institutes

Pharmaceutical companies

Companies in the medical sector

Options

Colour measurement, layer thickness measurement

High accuracy when measuring the gap width

Roll bearing pressure measurement

Melt temperature measurement via IR sensor

Torque measurement on each roll

Knead level measurement, adhesive force measurement

Sealing jaws adjustment for samples with low volume

Catalogs

No catalogs are available for this product.

See all of COLLIN Lab & Pilot Solutions GmbH‘s catalogsOther COLLIN Lab & Pilot Solutions GmbH products

LAB-Line

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.