- Medical & Pharmaceutical industry

- Medical industry

- Continuous cartoner

- Harro Hoefliger Verpackungsmaschinen

- Products

- Catalogs

- News & Trends

- Exhibitions

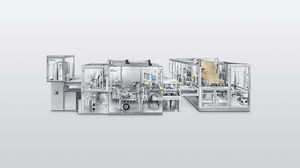

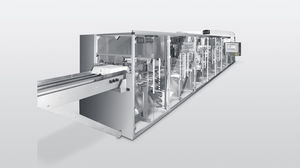

Continuous cartoner MKChorizontalfloor-standingfor sterile materials

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Operational mode

- continuous

- Type

- horizontal

- Configuration

- floor-standing

- Product applications

- for sterile materials

- Container type

- blister, for vials, bottle

- Application domain

- for the pharmaceutical industry

- Other characteristics

- modular

- Production capacity

100 p/min, 200 p/min, 300 p/min

Description

Thanks to different modules for product feeding, product transport, product insertion and folding box closure, the cartoner MKC can be configured in an optimal way to meet customer requirements. With various closure types, product infeeds and customized solutions available, the MKC can be flexibly adapted. This horizontal cartoning machine ensures a safe and gentle transport, loading and insertion of the products into the folding box (side-loading). Even existing top-loader applications can be easily adapted to the horizontal MKC, by minor adjustments to the folding boxes, e.g. top-opening cartons for product presentation at its best.

Benefits

Highest flexibility as a result of modular design for solutions tailored specifically to customer needs.

Ease of use with movable touch panel and state-of-the-art visualization technology, low construction and ergonomic machine design for optimal accessibility.

Ideal range of applications with highly dynamic servo drives and overload protection at all safety-relevant machine functions.

Set-up of all common folding box closure variants in large format range (adjustment options with reproducible settings) and

customized closure options, plus up to two closure variants on one machine

Ability to add on various feeding systems and to expand the system with serializing functions

Product insertion from the rear (side-loading) ensures a clear machine front and optimal accessibility of the packaging area

Product feeding

Product feeding plays a critical role in packaging machines. Harro Höfliger has a large repertoire of product handling systems.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Harro Hoefliger Verpackungsmaschinen‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Other Harro Hoefliger Verpackungsmaschinen products

Packaging

Related Searches

- Pharmaceutical product packaging machine

- Automatic packaging machine

- Floor-standing packaging machine

- Filler for the pharmaceutical industry

- Automatic filler

- Sealing packaging machine

- Blister packaging machine

- Floor-standing filler

- Compact packaging machine

- Medical industry packaging machine

- Liquid filler

- Medicine packaging system

- Film packaging machine

- Horizontal packaging machine

- Continuous packaging machine

- Cartoner for the pharmaceutical industry

- Intermittent packaging machine

- Solids packaging machine

- Automatic cartoning machine

- Table filler

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.