- Medical & Pharmaceutical industry

- Medical industry

- Automatic cartoner

- Harro Hoefliger Verpackungsmaschinen

- Products

- Catalogs

- News & Trends

- Exhibitions

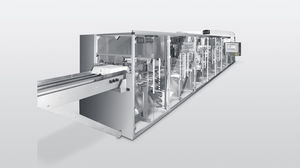

Automated cartoner MCPintermittentfilmfloor-standing

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Operational mode

- automated, intermittent

- Type

- film

- Configuration

- floor-standing

- Application domain

- for the pharmaceutical industry

- Options

- sealing

- Production capacity

10 p/min

Description

In the MCP Casepacker, folding boxes are fed onto a single track, grouped and stacked. The boxes can be packed either via side loading or via wrap-around. Serializing functions make it possible to detect the separate folding boxes and to label each individual shipping box.

Benefits

High performance end packaging system

Optimum accessibility

Rapid size changes with reproducible settings

Large range of formats of the packaging sizes

Consistent operating concept with touch panels

Extremely small footprint

Periphery

Assembly systems

Web processing machines

Film forming machines

Dosing and filling machines

Packaging machines

Handling systems

Multi-packaging

The last link in our assembly and packaging lines is the multi-packaging. Here, folding boxes are grouped, stacked and packaged for shipping. This is done either via side-loading in upright cartons or via wrap-around technology.

Automation

Automated logistics concepts control how product components are fed via feeding unit and regulate the transport systems within the machine. Robot and automation technology is used to insert components into the packaging machine.

Sealing

All common cartoning closing methods are used in Harro Höfliger packaging machines. Whether closing the box with carton flaps, by applying an adhesive, by placing a cover on it or with sealing wax. The Höfliger experts can even find the ideal technical solution for custom special closing methods.

Serializing

Our packaging machines can be easily equipped with serializing processes for the benefit of quality assurance and to increase protection from counterfeiting medicine.

Catalogs

No catalogs are available for this product.

See all of Harro Hoefliger Verpackungsmaschinen‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

Other Harro Hoefliger Verpackungsmaschinen products

Packaging

Related Searches

- Pharmaceutical product packaging machine

- Automatic packaging machine

- Floor-standing packaging machine

- Filler for the pharmaceutical industry

- Automatic filler

- Sealing packaging machine

- Blister packaging machine

- Floor-standing filler

- Compact packaging machine

- Medical industry packaging machine

- Liquid filler

- Medicine packaging system

- Film packaging machine

- Horizontal packaging machine

- Continuous packaging machine

- Cartoner for the pharmaceutical industry

- Intermittent packaging machine

- Solids packaging machine

- Automatic cartoning machine

- Table filler

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.