- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Epoxy medical assembly adhesive EP41SMedfor medical devicesmedical industrybiocompatible

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Chemical composition

- epoxy

- Applications

- for medical devices, medical industry

- Other characteristics

- biocompatible

Description

Two part epoxy system for bonding, sealing, coating and potting that meets USP Class VI and ISO 10993-5 for medical applications

Key Features

Very fast curing; quick handling time

Highly resistant to chemical sterilants

Exellent physical strength properties

Outstanding electrical insulation properties

Master Bond EP41SMed is a two component epoxy system that combines swift curing along with impressive chemical resistance, particularly to sterilants used in medical applications. EP41SMed meets USP Class VI and ISO 10993-5 specifications. This lower viscosity system has a 100 to 20 non-critical mix ratio by weight. It sets up quickly after mixing and typically can be removed from a fixture in 40-50 minutes. It cures in 24 hours at 75°F, in 60-90 minutes at 200°F. To obtain optimum properties, curing overnight at 75°F followed by 1-2 hours at 150-200°F is recommended.

As noted above, EP41SMed has sterling chemical resistance. Typically, faster curing epoxies are somewhat less chemically resistant than other types of systems. However, EP41SMed excels at withstanding many chemical steriliants, including ethylene oxide, bleach, glutaraldehyde, hydrogen peroxide based systems and peracetic acid type compounds, among others.

EP41SMed is 100% reactive and does not contain any diluents or solvents. It bonds well to a wide variety of substrates including metals, composites, ceramics and glass along with many plastic and rubber materials.

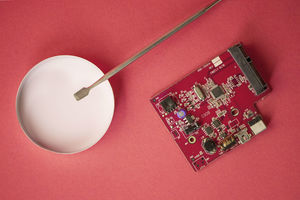

EP41SMed is a highly reliable electrical insulator and is particularly well suited for use in small sized potting applications. Most importantly, it has minimal shrinkage upon curing.

Catalogs

No catalogs are available for this product.

See all of Master Bond‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.